O que torna as porcas quadradas uma escolha superior para fixação industrial?

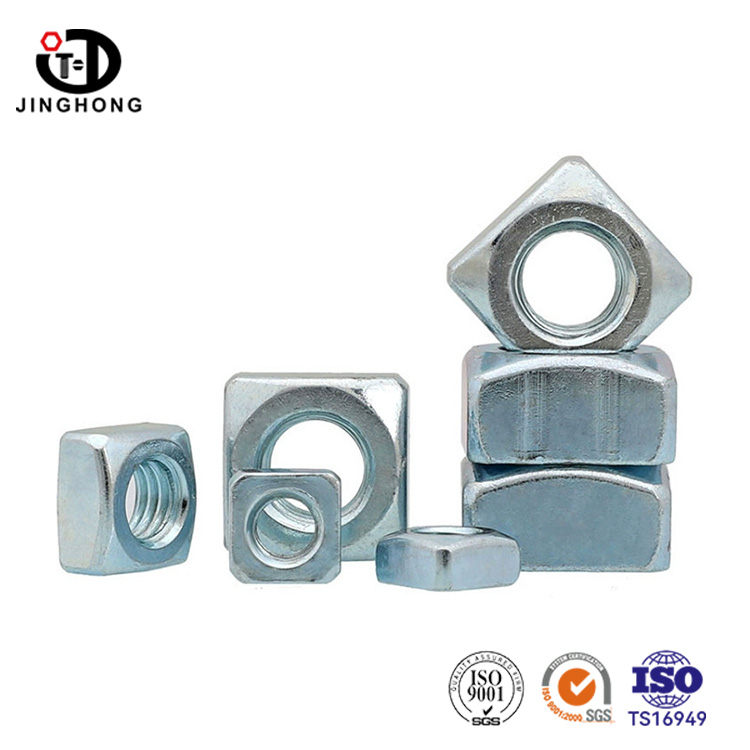

Square nuts, a fundamental component in mechanical assemblies, have been widely used across construction, automotive, and industrial machinery sectors. Their unique four-sided design provides higher torque resistance, stable fastening, and an even distribution of pressure compared to traditional hex nuts.

Square nuts are typically manufactured from high-strength stainless steel, carbon steel, or alloy steel, and are often treated with coatings such as zinc plating, black oxide, or galvanization for enhanced corrosion resistance. Their precise thread design ensures compatibility with standard bolts while offering additional surface contact to prevent loosening in vibration-heavy environments.

The following table summarizes the core technical parameters of square nuts:

| Parameter | Specification Range |

|---|---|

| Material | Stainless Steel, Carbon Steel, Alloy Steel |

| Thread Size | M3 to M36 (Metric), #4 to 1-1/2" (Imperial) |

| Thread Type | Coarse Thread, Fine Thread |

| Hardness | HRC 18–28 (Stainless), HRC 30–40 (Carbon Steel) |

| Surface Treatment | Zinc Plated, Black Oxide, Galvanized, Nickel Plated |

| Tensile Strength | 400–1200 MPa depending on material grade |

| Standard Compliance | ISO 4032, DIN 557, ANSI B18.2.2 |

| Operating Temperature | -40°C to 250°C depending on material |

| Applications | Machinery, Automotive, Electrical Panels, Structural Fastening |

The structured design and versatility of square nuts make them indispensable in applications requiring high load resistance, precise alignment, and long-term reliability.

Why Are Square Nuts Preferred Over Other Fasteners in High-Stress Environments?

Square nuts offer several advantages that set them apart from hex or wing nuts, particularly in applications where vibration, torque, or misalignment are concerns. The four-sided geometry provides increased surface contact with the material being fastened, reducing the risk of rounding off edges during tightening. This ensures that assemblies maintain structural integrity even under high dynamic loads.

In addition to mechanical strength, square nuts excel in low-clearance or confined installations. Unlike hex nuts, which require more rotational space for wrenches, square nuts allow easier tool access in narrow gaps or recessed areas, speeding up assembly while reducing labor costs.

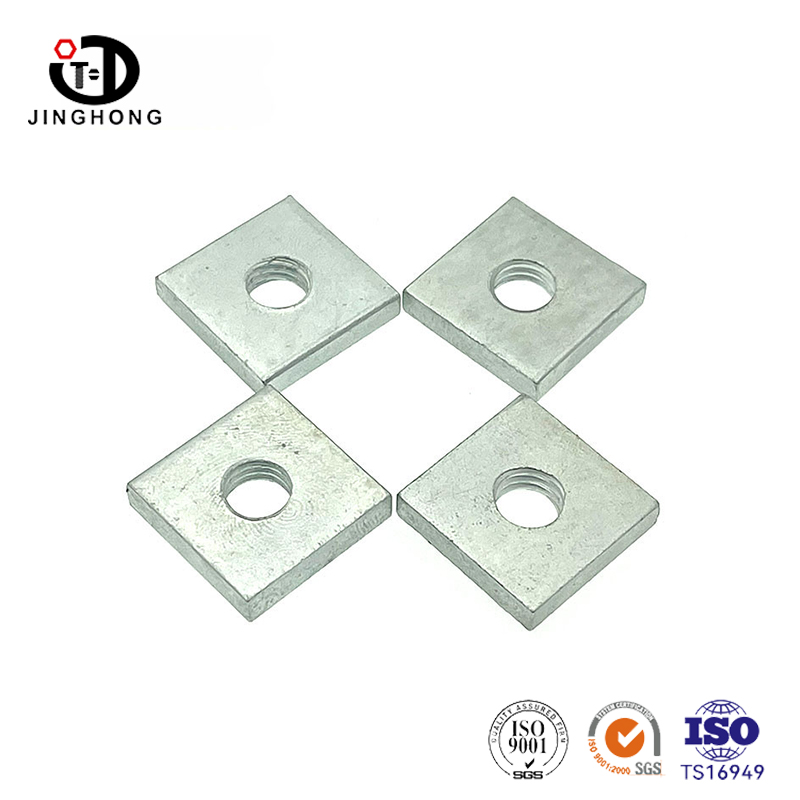

Another reason for their popularity is their superior locking performance when paired with washers or used in threaded channels. Their larger bearing surface distributes pressure evenly, preventing stress concentration and material deformation. This makes them ideal for woodworking, metal fabrication, and machinery maintenance where consistent load distribution is critical.

Key Benefits of Square Nuts:

-

Enhanced Torque Resistance: The square design prevents slippage under high torque conditions.

-

Durability: Manufactured from high-grade steel, resistant to wear and deformation.

-

Corrosion Resistance: Coatings such as galvanization and zinc plating extend lifespan.

-

Ease of Installation: Four-sided access allows faster tightening and loosening in restricted spaces.

-

Versatility: Compatible with various bolt sizes and threads, suitable for multiple industries.

These characteristics make square nuts not just a traditional fastener, but a practical solution for modern industrial demands.

How Can Square Nuts Improve Efficiency and Safety in Assembly Operations?

Square nuts are instrumental in achieving efficient and safe assembly in industrial and commercial applications. The combination of mechanical strength, stability, and ease of installation reduces downtime and maintenance costs. Engineers often choose square nuts for machinery that experiences repeated vibration or thermal expansion, as they maintain tightness without frequent readjustments.

The manufacturing precision of square nuts ensures that thread tolerances match standardized bolts, minimizing the risk of cross-threading. Additionally, their geometric stability allows for uniform load distribution, which is critical for maintaining the alignment of structural components.

Applications and Industry Use Cases:

-

Construction and Structural Engineering: Square nuts are used in scaffolding, steel frameworks, and prefabricated structures to maintain tight connections under heavy load conditions.

-

Automotive and Transportation: Essential in vehicle chassis, engine mounts, and suspension systems where vibration resistance is critical.

-

Electrical Panels and Machinery: Provide secure fastening for components in tight enclosures, reducing maintenance cycles.

-

Woodworking and Metal Fabrication: Square nuts in combination with washers prevent splitting in wood and deformation in soft metals.

By selecting the appropriate material and thread type, industrial operators can optimize square nut performance for specific operational demands. For instance, stainless steel square nuts are ideal for outdoor or corrosive environments, while carbon steel variants provide cost-effective solutions for general manufacturing applications.

Common Questions About Square Nuts:

-

Q: Can square nuts handle high-vibration environments without loosening?

A: Yes, the larger bearing surface and four-sided design distribute load evenly, reducing the risk of loosening. When combined with lock washers or thread-locking compounds, square nuts maintain secure fastening even under continuous vibration. -

Q: How should one select the correct material and coating for square nuts?

A: Material choice depends on the operating environment and load requirements. Stainless steel is recommended for corrosion resistance, carbon steel for standard mechanical strength, and alloy steel for high-stress conditions. Surface coatings like zinc plating or black oxide further protect against rust and extend service life.

What Is the Future Trend of Square Nut Applications in Industrial Fastening?

The demand for high-performance, reliable fasteners continues to grow as industries evolve toward automation, heavy machinery, and precision engineering. Square nuts are expected to remain relevant due to their mechanical advantages and adaptability. Emerging trends include:

-

Advanced Materials: The use of heat-treated alloys and high-grade stainless steel improves load capacity and corrosion resistance.

-

Precision Manufacturing: CNC machining and automated threading processes ensure tighter tolerances and enhanced assembly consistency.

-

Sustainability: Eco-friendly coatings and materials reduce environmental impact while maintaining durability.

-

Specialized Designs: Square nuts with integrated locking features or custom dimensions for specific industrial applications are gaining popularity.

These developments indicate that square nuts are not just a legacy fastener but a component evolving with industry requirements, combining tradition with innovation.

Incorporating reliable fasteners such as Jinghong Fasteners® square nuts ensures consistent quality and performance. With a focus on precision, durability, and industrial compatibility, Jinghong Fasteners® provides products that meet both current and future demands. For detailed inquiries or bulk orders, contact us to learn more about our full range of square nuts and related fastening solutions.